(Fortune) Your next Friday night pizza may be made by robot hands.

That’s the vision of Ajay Sunkara, who launched the Pizzaiola autonomous chef, an A.I.-driven, voice-controlled pizza maker that’s making its way to Chicago-based regional pizza chain, Slice Factory. The robotic chef monitors more than 1,200 parameters every microsecond, from managing food quality to the point-of-sales machine.

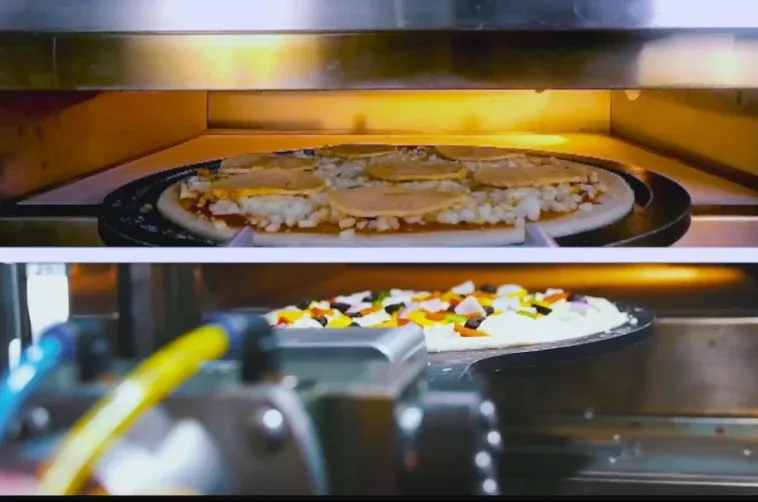

When a customer places a pizza order, Pizzaiola will select, press, and stretch the dough; add the sauce, cheese, and toppings; then cook, slice, and box the pizza all to the customer’s specified preferences. It’s fulfilled in real time and can even have an individual jumbo slice ready to go through the Slice Factory drive-thru in minutes.

Not a single human touch is involved.

“There are robotics in the food industry, but in factories, meat-processing centers, and packaged food processing,” Sunkara tells Fortune. “We reduced the scale of it from industrial to something that can fit in a normal commercial kitchen.”

Pizzaiola is the newest product from Sunkara’s Nala Robotics, the kitchen robotics company he founded in 2017. Sunkara, who now serves as the company’s chief executive officer, said that he saw an opportunity to innovate in the back of the house in food service; until then, most new products for the hospitality industry focused on point-of-sale, reservations, and guest experiences. His foundational product, Nala Chef, is a multi-cuisine, customizable robot chef that serves a range of dishes at Nala’s three proprietary restaurants in Naperville, Ill.: One Mean Chicken, a fried chicken concept; Surya Tiffins, a South Indian eatery; and Thai 76, a fast-food Thai spot.

Core to Sunkara’s automated chef is artificial intelligence. Sunkara recruited friend and chief technology officer Vijay Kodali to employ machine learning for the robot’s operating system, dubbed Yum OS. What they built is a robot that not only learns intellectually as a human would, but can pull from all five “senses.” The robot chef can touch, smell, see, hear, and even taste, thanks to a tasting bar that mimics the human tongue. The senses send feedback to the OS, creating a learning loop similar to a human’s, which logs all information for future use. It’s as if the robot is constantly in a culinary school class, but remembers every detail from the homework.

“Multiple senses all provide data in a way that we can make an intellectual decision,” Sunkara says. “That’s the A.I. process as well.”

Sunkara explained that the robot tracks all inputs, including customer feedback. If a customer complains that a pizza was too salty or a pad thai too spicy, it will use that data in future production.

It all harks back to the inspiration for the robot chef: consistency. Sunkara’s aha moment came from beer tasting, when he realized that automated beer production leads to uniform aromas, flavors, and balance from draft to draft, bottle to bottle. But when he looked at restaurant food production, it was largely human-powered, leading to subjective tastes and inconsistencies in the final product.

The A.I. is not just programmed to make a pepperoni pizza and chicken tikka, but can invent dishes as well. Give it a list of ingredients, and it will pull from its knowledge of Chinese, Indian, Thai, and American cuisines to create a meal.

Though the A.I. system powers the device, the mechanical side physically prepares the meal. Sunkara noted that robotic arms have become significantly more affordable in the past decade, increasing the average fast-casual restaurant’s ability to purchase such a machine. (His Pizzaiola robots lease at $7,000-plus per month, but he says they save on similar labor costs over a three-year period.)

Other robot chef products exist in the space, and the adoption is promising. It’s been accelerating especially since the pandemic, said Rajat Bhageria, founder and CEO of Chef Robotics. Bhageria’s products serve as a substitute for a human assembly line cook in commercial kitchens at fast-casual restaurants and ghost kitchens. He provides “robotics as a service”—robots that are easily configurable to work with different ingredients, portion sizes, containers, and placements within the containers. The result is an adaptable system that can mimic the flexibility of a person, he said.

Bhageria explained that the line cook job has a massive turnover rate, according to the Bureau of Labor Statistics, and restaurants are routinely understaffed by 20% to 50%. The job requires “redundant motions while standing up,” something easily swapped to automation. That frees the human for other, more comfortable, advanced, or rewarding work.

There are upsides to a robotic environment at a time when the hospitality industry faces a major labor shortage, especially as a result of COVID-19, and labor costs have increased with a rise in the minimum wage in states like California.